From waste to watts: How General Mills turns yogurt into power.

It might sound like science fiction, but in Murfreesboro, Tennessee, yogurt waste is helping power the grid. At General Mills’ massive facility—home to iconic brands like Pillsbury and Yoplait—a clever use of dairy byproducts is reducing emissions, improving resilience and offering a model that other manufacturers could follow.

Here’s how it works — and why it matters.

What’s in yogurt waste? And why it’s powerful.

Greek yogurt production generates a significant amount of byproduct known as acid whey — a nutrient-rich liquid that’s expensive to dispose of and challenging to manage. But it also happens to be full of organic material that breaks down well in a process called anaerobic digestion.

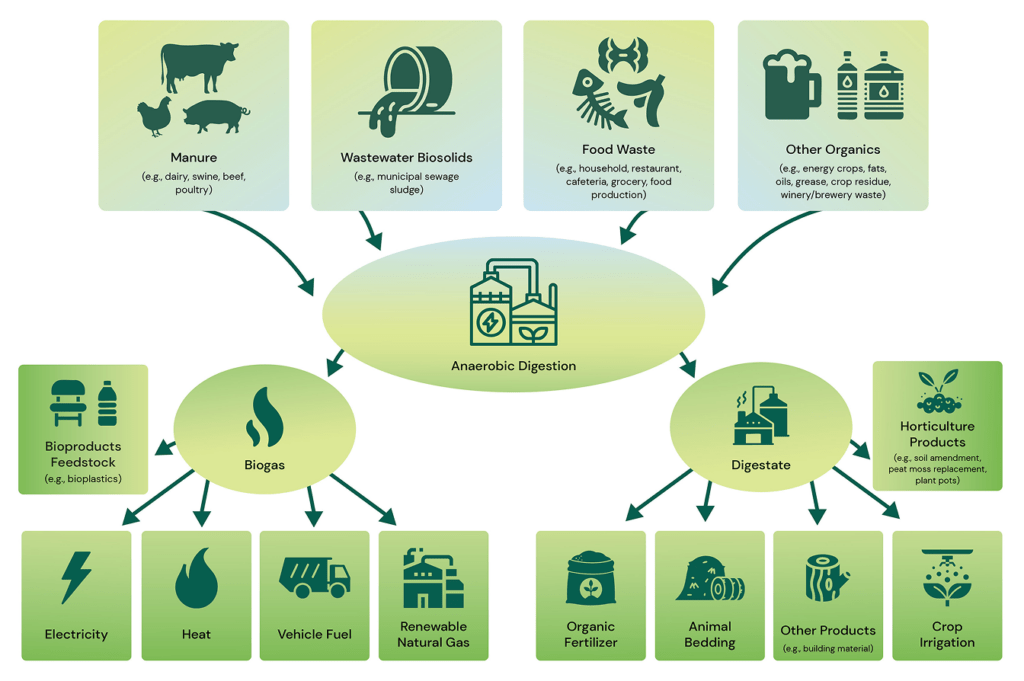

Anaerobic digesters are machines that break down food and plant waste using tiny microbes (like bacteria) that don’t need oxygen. As the microbes consume the waste, they produce a methane-rich gas, also known as biogas, which can be used to generate electricity.

At General Mills’ Murfreesboro plant, that biogas is used to power a 1.6-megawatt generator, supplying energy right back to the facility and offsetting fossil fuel use. Even better? The leftover material (digestate) can sometimes be repurposed as fertilizer.

Sources: epa.gov; generalmills.com

Why is the Middle Tennessee plant location unique?

The General Mills site is unique not just for its size — it’s one of the largest Yoplait producers in the country — but for its on-site wastewater treatment plant. Plus, with a demand load exceeding 15 megawatts — one of only four General Mills plants globally to reach that threshold — the facility’s energy performance has a significant impact on both operational efficiency and sustainability goals. When the facility expanded to accommodate Greek yogurt production, it invested in an anaerobic digester to handle the acid whey and other organic waste.

With support from federal clean energy tax credits and strong technical assistance from Middle Tennessee Electric (MTE), the plant was able to safely integrate the generator into the grid. That partnership was essential to making the system viable — not just technically, but economically.

Daren Kaiser, Global Energy Strategy Leader for General Mills, says, “We got 40% of that cost covered by a federal rebate, but the real win was Middle Tennessee Electric’s willingness to partner with us. MTE was with us every step of the way. They probably worked harder than our contractors to make sure it came together. That kind of partnership makes innovation possible.”

What’s the impact?

The anaerobic digester is a low-emission, high-reward system that helps General Mills:

- Reduce a facility’s Scope 1 emissions (by burning natural gas).

- Save on waste disposal costs.

- Generate renewable electricity.

- Increase energy resilience for a plant that operates 24/7 and can’t afford outages.

- Keep valuable nutrients out of landfills or waterways.

The anaerobic digester at General Mills provides a powerful win-win for business and the environment. Beyond reducing Scope 1 emissions and cutting waste disposal costs, it generates clean, reliable power — perfect for a plant that can’t tolerate downtime. Plus, the digestate, a semi-solid material left over from the anaerobic digestion process, can be used as fertilizer, keeping nutrients in the loop rather than allowing them to leach into landfills or waterways.

Source: cen.acs.org

Can other industries do this, too?

Yes! Anaerobic digestion is also being used by:

- Food and beverage manufacturers (especially dairy, meat and produce)

- Breweries (spent grains and yeast waste)

- Agriculture (manure and crop waste)

- Municipalities (food scraps, sewage sludge, biosolids)

The keys to success? A consistent waste stream with sufficient volume to justify the system, and strong local utility partnerships to help manage grid integration and incentives.

For companies under pressure to meet sustainability goals without sacrificing uptime or margins, anaerobic digestion offers a compelling win-win. What starts as a byproduct of creamy Yoplait ends up fueling the plant that makes it. In a time of increasing energy demands, turning waste into energy might be one of the smartest, most scalable strategies available.

Sources: epa.gov

Ready to take the next step?

Connect with your local power company or with one of our TVA Energy Experts to explore energy-efficiency options tailored for your business or facility.

Is a heat pump water heater right for your home?

Thinking about replacing your old water heater? Good news — heat pump water heaters (HPWHs) might just be one of the smartest, most reliable investments you can make for comfort, savings and peace of mind.

Here’s what we’re going to cover in this article to help you decide whether or not a heat pump water heater is right for your home:

- A (very) brief history of heat pumps.

- How’s a heat pump water heater different from an electric resistance or gas water heater?

- Key benefits of heat pump water heaters.

- Types of residential heat pump water heaters.

- Installation best practices.

- Myths about heat pump water heaters.

- Market trends.

A (very) brief history of heat pumps.

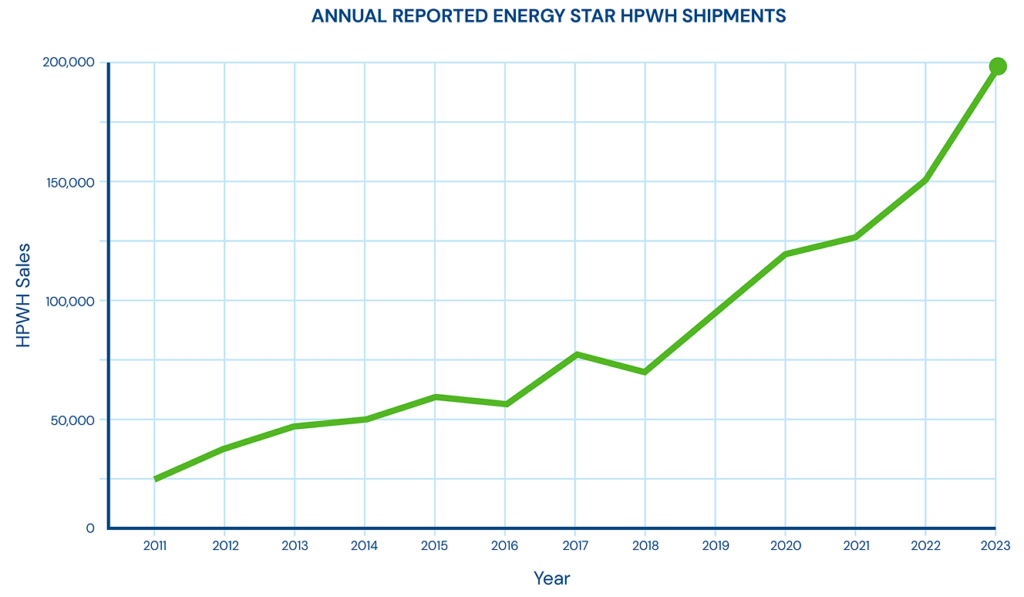

The heat pump technology has been around since the 1850s and was widely adopted in the early 20th century, when early refrigeration systems were being developed. Air-source HPWHs burst onto the scene in the 1970s — and the technology has been improving by leaps and bounds ever since. Today, more and more manufacturers are entering the market each year, helping HPWHs become the fastest-growing type of water heater (New Buildings Institute).

How’s a heat pump water heater different from an electric resistance or gas water heater?

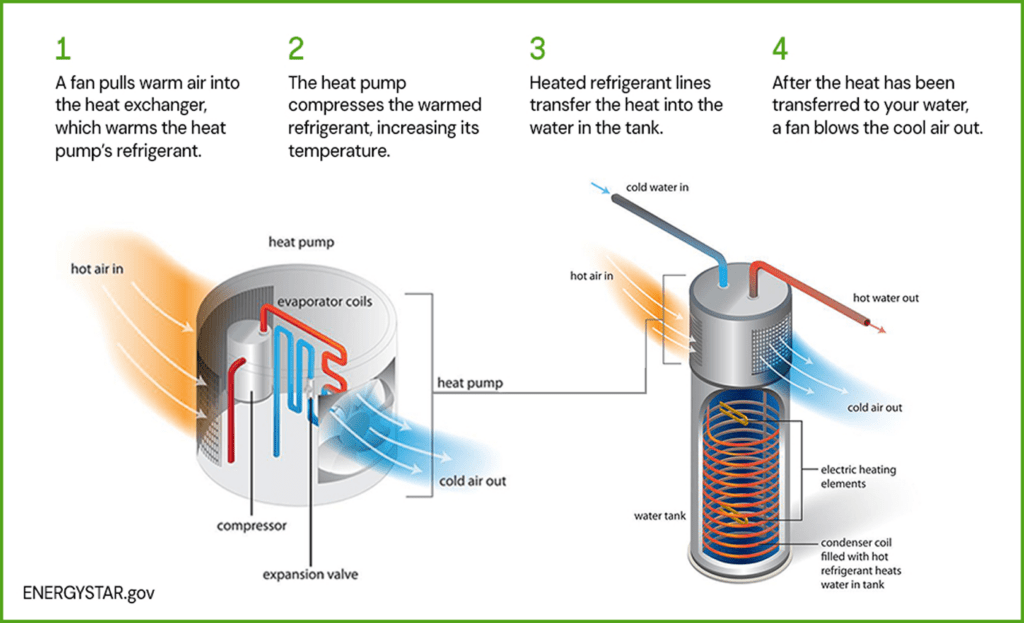

It’s all about how they work. It’s ingenious, really. Instead of generating heat through combustion or electrical resistance — like a conventional water heater — HPWHs transfer heat, using a compressor and refrigerant.

They’re kind of like your refrigerator, except running in reverse. Instead of fighting the cold by heating water, they pull warmth from the air around them and transfer it into your water tank.

6 top benefits of heat pump water heaters.

Although the initial costs for HPWHs are higher than standard electric or gas units, rebates of up to $1,300 may be available AND they offer immediate and long-term savings. Here’s a look at the key benefits of HPWHs.

#1. Energy savings

The highly efficient technology enables ENERGY STAR® certified HPWHs to consume up to 70% less energy than standard models. Which, in our seven-state region, boils down to a household of four saving up to $300 per year on electric bills!

#2. Rebates and incentives

Homeowners in the Tennessee Valley region can get an instant rebate of up to $1,300 through our Quality Contractor Network, and in stores and online at participating retail locations.

#3. Longevity

On average, HPWHs last slightly longer than conventional water heaters, with fewer breakdowns. A conventional water heater has a life span of 8-12 years and with proper maintenance, HPWHs can last about 12-15 years.

#4. Improved air quality

HPWHs do not create toxic combustion exhaust gases, such as carbon monoxide. And, because they don’t rely on combustion they minimize the risk of fire or explosion that can be caused by a fuel-fired water heater or associated gas piping.

#5. Increased control

Many models allow access to settings — such as temperature setpoints and operational modes — via a digital control panel or app.

#6. Bigger energy savings

Switching to a HPHW will save about 2800 kWh annually per household, that is 2X the saving opportunity that LEDs provided! (Nate Jutras, ENERGY STAR)

Types of residential heat pump water heaters.

There are a few different types of HPWHs, each designed for different types of homes and needs. Here are two kinds of systems that work well in our region:

Unitized 240v hybrids

The most common type of HPWH, these hybrid systems combine the flexibility of electric resistance heat with the benefits of an integrated heat pump water heater. These are great options for households with high hot water demands.

Split systems

As the name indicates, the heat pump is separate from the water tank, allowing for more flexibility in placement and installation. A solid option for tighter spaces.

Installation best practices.

To perform efficiently and reliably, HPWHs need airflow.. Most manufacturers and ENERGY STAR recommend about 700 to 1,000 cubic feet of free air space. That translates to a room that’s roughly 8×8 ft up to 10×10 ft or even larger. Although some manufacturers make units that can be installed in spaces as small as 450 cubic feet. All units are different, so always refer to manufacturer requirements!

Why so much space? Because HPWHs draw in air to extract heat, and in tighter spaces, they can’t breathe properly — making them work harder and less efficiently. If they’re located in a cramped closet without proper ventilation, they may rely too heavily on their electric heating backup.

Since HPWHs draw warmth from the surrounding air, they should be located in an area with a minimum temperature of 37° F. If your laundry room is large enough, that could be an ideal location, as heat-emitting appliances can help them run even more efficiently.

Although today’s HPWHs are significantly quieter than their predecessors, installers should avoid placing them next to bedrooms or home offices.

Finally, don’t forget about condensate! Your unit will produce water that you’ll need to drain away, using a floor drain or a condensate pump.

A member of TVA EnergyRight’s Quality Contractor Network can help ensure your new water heater is installed for maximum efficiency.

Busting a few myths about heat pump water heaters.

Heat pump water heaters are too noisy!

Today’s heat pump technology is far more efficient — and quiet — than previous generations. An intermittent soft humming sound of the compressor is normal for an ENERGY STAR Heat Pump Water Heater — typically in the range of 45 – 50 dBA. To put that into perspective, that’s quieter than normal conversation.

They’re too expensive to service.

Unlike conventional water heaters, which usually have a 6-year warranty, HPWHs often come with at least a 10-year warranty. And if your plumber has hesitations about servicing a compressor, simply contact the manufacturer — if it’s under warranty, odds are they’ll take care of it.

They’ll make my house too cold and increase heating costs.

HPWHs produce a small amount of cool, dry air, but extensive research has found the effect is negligible, usually in the range of 2°-5° F of localized cooling around the unit.

Market trends.

Questions?

Reach out to a member of the Quality Contractor Network to learn more about HPWHs. Don’t forget to ask about our instant rebate!