Are your compressed air systems the hidden energy drain in your facility?

Compressed air is one of the most widely used utilities in industrial facilities — and one of the most expensive to operate. Because it operates quietly in the background, inefficiencies often go unnoticed until energy costs start to rise and equipment performance declines. For many facilities, aging compressed air systems are quietly consuming more energy than necessary, creating an opportunity for smarter upgrades.

The good news: Modernizing compressed air systems for efficiency doesn’t have to mean over-the-top capital costs. With new Fast Track Compressed Air incentives, custom incentives and free online training, TVA EnergyRight® is helping industrial facilities address inefficiencies, plan upgrades strategically and improve long-term performance.

Why compressed air system efficiency deserves a closer look.

Compressed air plays a critical role in manufacturing, powering pneumatic tools, processing, packaging and material handling. But it’s also one of the least efficient forms of energy. Compressed air is an on-site-generated utility, and it is also one of the most expensive sources of energy in a plant. The overall efficiency of a typical compressed air system can be as low as 10%-15%.

Studies show that up to 30% of compressed air energy may be wasted in aging, improperly sized or poorly maintained systems. Because this waste accumulates gradually, it often goes unnoticed during day-to-day operations.

Even small issues can add up quickly. For example, a quarter-inch air leak operating at 100 psi can waste more than $2,500 in electricity each year. Across an industrial facility with multiple compressors and extensive piping, those losses can add up fast.

Unlike other utilities, compressed air inefficiencies don’t always present as a single failure. Instead, facilities may experience creeping energy costs, declining system responsiveness or increasing maintenance demands. That means that the system is working harder than it should, and that work consumes extra energy, costing you more.

Sources: energy.gov; gasoutlook.com; usaircompressor.com

The real cost of aging compressed air systems.

Many industrial facilities still operate compressed air systems installed years or even decades ago. While these systems may still function, their efficiency and performance often decline over time.

Challenges include:

- Increased energy consumption to deliver the same air output.

- Higher maintenance costs and unplanned downtime.

- Equipment running outside optimal load ranges.

- Running a system at a higher pressure than necessary.

- Difficulty justifying upgrades without clear financial support.

As production needs change, older systems are often left mismatched to current operations, resulting in excess energy use and reduced reliability.

Source: energy.gov

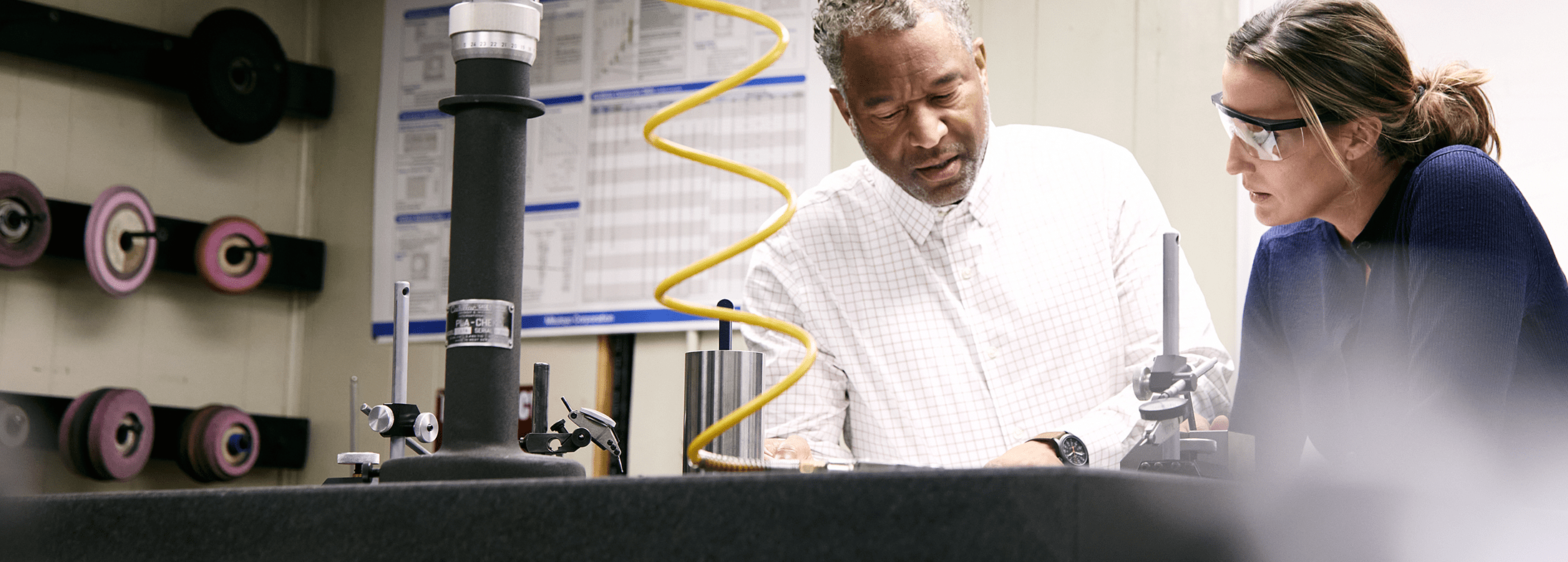

Where energy losses typically occur.

Compressed air energy efficiency isn’t limited to one component. Instead, it’s usually the result of a combination of system-level issues, including:

- Outdated compressors operating inefficiently under partial or excessive loads.

- Inefficient air treatment and filtration, increasing pressure drop and energy demand.

- Poor system controls or sequencing, leading to unnecessary run time.

- Equipment sized for past production needs, not today’s operating reality.

Addressing these efficiency issues requires more than maintenance. It often requires strategic system upgrades. And that’s where industrial energy incentives with TVA EnergyRight and your local power company come in. Here are three tools you can use to upgrade your compressed air system’s energy efficiency.

Source: energy.gov

Smarter compressed air starts here.

1. Fast Track Compressed Air incentives: A smarter path to upgrades.

To help facilities move forward with necessary improvements, TVA EnergyRight offers Fast Track Compressed Air incentives designed to reduce the up-front cost of new equipment and specific parts replacements, such as condensate drains and engineered air nozzles.

These incentives:

- Lower costs for compressed air component upgrades.

- Simplify the incentive process to speed up upgrades.

- Support improvements that enhance efficiency, reliability and performance.

Fast Track Compressed Air incentives help turn required upgrades into smarter business moves with a clearer ROI.

Learn more about our Fast Track Compressed Air incentives and see how you can start saving.

2. Custom Incentives for full system replacements.

There is a lot of flexibility with Custom incentives. For targeted improvements with existing compressed air systems to full replacements, Custom incentives provide flexible support based on project scope and energy savings.

This approach allows facilities to modernize strategically — aligning improvements with operational needs and capital planning timelines.

To learn more about Custom incentives, connect with a TVA Energy Expert.

3. Build in-house expertise with Compressed Air Training

Incentives are most effective when paired with knowledge. The first step for any compressed air system is to optimize existing equipment. That’s why TVA EnergyRight offers a free, online Compressed Air Training course with two 4-hour sessions, valued at more than $400.

The course is designed for facility managers, engineers and energy professionals. It focuses on:

- Practical strategies that can be implemented immediately.

- Understanding system performance and optimization.

- Identifying opportunities for ongoing energy savings.

Facilities that apply these strategies typically save 15-25% on annual energy costs, making training a powerful resource alongside system upgrades.

Learn more or register for our Compressed Air Training webinar here.

From cost center to competitive advantage.

TVA Energy Experts can help your facility navigate this process by providing proven pathways that support smarter planning, stronger performance and long-term results.

When compressed air systems are modernized and well managed, they do more than just reduce energy costs. They support productivity, improve reliability and give facilities greater control over operating expenses. With the right mix of incentives, training and expert guidance, compressed air can shift from a hidden cost to a strategic asset.

Ready to start? Here’s how.

Optimizing compressed air systems can cut energy use, lower operating costs and boost efficiency. Connect with a TVA Energy Expert to see how we can help your facility cut costs and save more.