Essential energy upgrades: Your complete guide to duct sealing, air sealing, insulation and HVAC maintenance.

Welcome to your home efficiency playbook.

Index

Click on the links to jump to the sections that are most relevant to you and your home.

- Introduction

- Chapter 1: Duct sealing

- Chapter 2: Air sealing (AKA: Home envelope sealing)

- Chapter 3: Insulation

- Chapter 4: HVAC Maintenance

- Chapter 5: How to hire a qualified HVAC contractor

- Glossary

Whether you’re a renter, homeowner or landlord who’s considering upgrading aging systems, understanding the fundamentals of home energy efficiency is important. We’re working closely with local power companies throughout the seven-state Tennessee Valley region to help people like you lower your energy bills with energy-saving recommendations, rebates and more.

Although we often think about each of these systems individually, they all work together to improve comfort, protect indoor air quality, lower your monthly heating and cooling costs, and extend the effective lifespan of your HVAC system.

That’s why we’re taking this opportunity to put everything you need to know about duct sealing, air sealing, insulation and HVAC in one place for easy reference. We hope you’ll find this comprehensive playbook useful and share it with your neighbors!

As you read through this guide, you’ll find expert-backed tips from energy authorities like ENERGY STAR, the U.S. Department of Energy (DOE), the U.S. Environmental Protection Agency (EPA), research publications and building-science standards from Air Conditioning Contractors of America (ACCA). Feel free to click around and keep on learning from trusted sources.

And don’t forget duct sealing, air sealing, insulation and HVAC maintenance all qualify for rebates from TVA EnergyRight and your local power company.

Chapter 1: Duct sealing.

Why duct sealing matters.

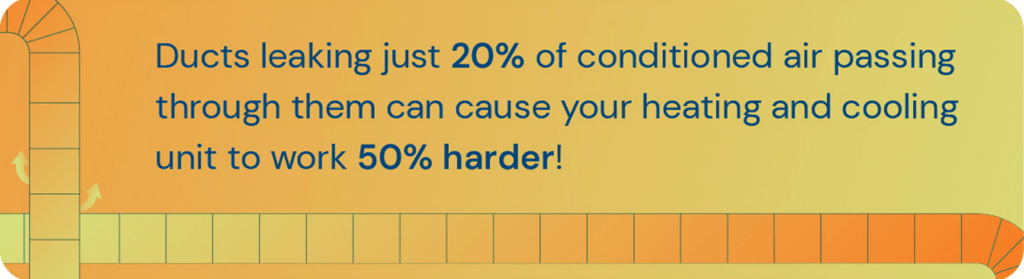

Wasting energy before it enters your home is hard on your home energy bills — and your personal comfort. Unfortunately, it’s an incredibly common way for energy loss to occur. Research shows that leaky ducts can lose a staggering amount of conditioned air — up to 30% — as it travels through the system.

Not only does this waste lead to higher energy bills, but it also means your HVAC system is working much harder than it needs to. Ducts leaking just 20% of conditioned air passing through them can cause your heating and cooling unit to work 50% harder!

Reading the signs.

What you can’t see can hurt your energy bill. For the most part, your home’s ductwork won’t be visible to you. However, just because you can’t see a crack or feel a leak doesn’t mean your home won’t give you some helpful signs that maintenance is needed. If any of the following symptoms sound familiar, it may be time to consult with your local heating and cooling expert.

- Higher-than-normal or unpredictable energy bills.

- Difficulty maintaining your desired temperature.

- Hot or cold spots or drafty rooms.

- Noticeable dustiness.

- Whistling or whooshing sounds when your HVAC runs.

- Dirt, dust, mold or condensation around air vents.

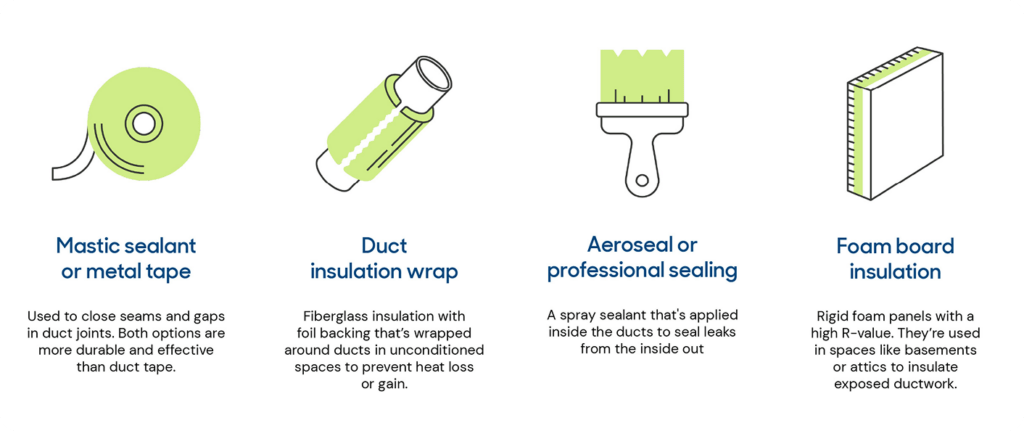

It may be tempting to run to your local hardware store and grab a roll of standard duct tape (quick note here: mastic sealant or metal tape are both more efficient, longer-lasting options), but unless you really know what you’re doing with your ductwork, you may want to leave maintenance to the professionals.

Best practices for duct sealing.

Use mastic sealant or foil-backed duct tape to seal all joints, seams and connections. Check out our duct sealing upgrade page for more information. Insulate ducts that run through unconditioned spaces such as your attic, crawl spaces and garage to reduce thermal loss.

When to call a duct sealing pro.

If you’re not confident in your DIY skills, if ducts run through hard-to-access areas, or need extensive sealing, a professional familiar with ACCA standards or local building codes is the way to go. If you suspect disconnections or serious leakage, you should look for a trusted expert. Plus, they’ll also have the equipment to run pre- and post-sealing leakage testing to help ensure the best results.

Chapter 2: Air sealing.

Why air sealing matters.

Air sealing is the process of closing small cracks, gaps and holes in your home’s building envelope — the barrier between indoors and outdoors. It’s especially important to have older homes inspected, but new construction shouldn’t get a free pass! As new homes settle, cracks and gaps often appear. Sealing up these gaps before winter (or summer) can dramatically reduce drafts, energy loss and discomfort.

Where to find air leaks in homes:

- Attic and crawlspace hatches.

- Window and door frames, sashes, jambs, sills.

- Plumbing and electrical penetrations (pipes, wires).

- Recessed lights, vents, fans and vent ducts.

- Around baseboards and where walls meet ceilings.

- Refrigerator, dishwasher or exhaust fan penetrations.

- Outlets, switch boxes and vent registers.

How to detect air leaks.

DIY-friendly and renter-friendly method.

For a low-cost preliminary check, you can take the DIY route. Here’s how:

- On a windy day, close all windows and exterior doors. Turn on exhaust fans (bathroom, kitchen hood).

- Light an incense stick (or use a damp hand) and slowly move around door frames, window edges, baseboards — feel or watch for air movement.

- Common leaks are at doors, windows, attic hatches, rim joists, plumbing or wiring penetrations and vents.

Want to get your kids in on the fun? Check out “Calling all junior detectives! Use your sleuthing skills to spot sneaky leaks.”

Why air sealing matters.

Lower energy bills: According to ENERGY STAR, air sealing and insulation can reduce heating and cooling costs by an average of 15%, and in some cases even more.

Improved comfort: Cut down on drafts, promote more stable indoor temperatures, reduce cold spots and take the burden off your HVAC systems. You can learn more about R-value (the higher the R-value, the greater the material’s insulating power) and find your climate zone on the Department of Energy’s website.

Better indoor air quality: Sealing leaks reduces infiltration of dust, pollen, mold spores, moisture and pests — which is especially relevant if vents, crawlspaces or attics are connected to living spaces.

Moisture and maintenance: Sealing leaks and home weatherization help prevent condensation, mold, mildew and structural damage from moisture infiltration.

Best practices for air sealing.

You don’t have to do everything at once! Remember, every improvement helps. To get started, we recommend focusing on key areas that can make the biggest difference.

Seal doors and windows.

- Use weatherstripping around doors and movable window sashes.

- Apply caulk to seal cracks around stationary window frames and exterior trim.

- Install door sweeps to block drafts at the bottom of exterior doors.

- Apply window film to especially drafty windows.

Address the attic and crawlspace.

- Look for gaps around plumbing vents, electrical wiring and chimneys in your attic.

- Use expanding foam or caulk to seal small holes and install covers or gaskets where needed.

- In crawlspaces, sealing gaps between the foundation and framing can stop cold air from entering your floors.

Chapter 3: Insulation.

Uneven temperatures, drafty rooms and high (or unpredictable) energy bills could mean your home is under-insulated or letting your conditioned air out and unconditioned air in!

Why insulation matters.

Insulation slows heat flow (via conduction, convection or radiation), helping keep warm air in during the winter or out during the summer months. Proper insulation reduces the load on your HVAC system and lowers energy use.

Types of Insulation.

The type of insulation you use may depend on where it’s being installed and your home’s specific needs. Some common insulation types include:

Blown-in (loose-fill) insulation

Ideal for attics and wall cavities, this type of insulation is made of fiberglass or cellulose and is blown into place using special equipment.

Batt insulation

These pre-cut panels of fiberglass or mineral wool are one of the most affordable and widely used forms of insulation. They’re ideal for open areas like between wall studs, floor joists and attic rafters.

Spray foam insulation

Expands to fill gaps and create a tight air seal. Available in open-cell and closed-cell varieties, spray foam is especially effective for sealing around pipes, wiring and small crevices.

Foam board insulation

Rigid panels made of polystyrene or polyurethane are typically used on foundation walls, basement interiors and exterior walls under siding. Foam boards offer high insulating value with a relatively thin profile.

R-value and where to insulate.

Insulation is measured in R-values, which indicate its resistance to heat flow — the higher the R-value, the better the insulation power. Visit our insulation and air sealing upgrade page for more information.

In the South, many homes are under-insulated — especially older houses. If the floor joists are exposed in your attic, for example, that’s a strong indication that you need additional insulation. Fortunately, rebates are available.

Insulation works best when the building envelope is tight. Installing insulation first, then sealing leaks, can leave gaps behind insulation or make leaks harder to find. Professionals and building-science guidance recommend sealing first, then insulating.

Here are key areas to consider for insulation:

- Attic insulation: Consider blown-in cellulose or fiberglass batt insulation to reach the recommended R-values for your region.

- Crawlspace insulation: Insulating the floor above the crawlspace can help maintain warmth on the first floor.

- Wall insulation: Harder to retrofit, but sometimes possible with dense-pack cellulose or foam injection.

You don’t always need a full insulation overhaul. Even topping off attic insulation or insulating around rim joists can make a big difference. Not sure where to begin? A member of our Quality Contractor Network can help.

For maximum efficiency, we recommend combining air sealing with insulation upgrades.

Chapter 4: HVAC maintenance

HVAC maintenance is essential for comfort, safety and efficiency — and helps prevent unexpected breakdowns when you need your system the most. We recommend scheduling a tune-up twice a year — once in fall (before heating season) and once in spring (before cooling season). Certainly, if you notice strange sounds coming from your unit and higher-than-normal bills, call in the pros regardless of whether your inspection is due or not.

If you have your home air sealed or insulated, it may be a good idea to add a tune-up to the list. Why? Because home envelope sealing may change airflow and pressure dynamics, which can affect how your system operates.

Why seasonal HVAC maintenance matters.

- Avoid costly emergency repairs — A well-tuned system is less likely to break down during extreme cold or heat.

- Improve energy efficiency: Clean systems run more efficiently and maintenance can catch issues (dirty coils, malfunctioning parts, airflow restrictions) that cause efficiency losses.

- Enhance indoor air quality: Regularly changing or cleaning filters helps trap dust, pollen and other particles rather than circulating them throughout the home.

- Extend equipment lifespan: Routine maintenance reduces wear and tear and lets you catch small problems before they become major.

- Ensure safety: Technicians can inspect for gas leaks, cracked heat exchangers, faulty wiring or improper ventilation — especially important if you have combustion appliances.

- Peace of mind: Proper airflow, clean components, calibrated thermostats — all lead to a more consistent, comfortable indoor environment.

- Take advantage of rebates: Get $50 off HVAC maintenance with a rebate from TVA EnergyRight and your local power company.

- Save money: Using less energy, helping your HVAC system last longer and taking advantage of rebates all add up to saving money.

What a typical HVAC maintenance visit should include.

Chat with your HVAC technician to make sure their inspection includes the following:

- Filter inspection/change.

- Coil cleaning (evaporator and condenser).

- Checking refrigerant levels (for cooling systems / heat pumps).

- Lubricating moving parts.

- Inspecting electrical connections and wiring.

- Testing safety controls, airflow and thermostat calibration.

- Checking defrost cycles and reversing valve in heat pumps.

Chapter 5: How to hire a qualified contractor.

Upgrades like duct sealing, air sealing, insulation and HVAC maintenance/installation often benefit from a trained, licensed and experienced contractor — especially when you want quality, safety and long-term performance.

What to look for in a trusted contractor.

We hope you’ll take advantage of our Quality Contractor Network (QCN) to find a TVA-vetted contractor near you. As you consider your options, keep the following recommendations in mind:

Licensing & insurance: Ensures compliance with state/local codes and protects you in case of accidents. (Members of the QCN are licensed and insured.)

Proven experience: Specifically, look for experience with the system and climate you have — whether that’s traditional furnaces/AC, heat pumps, ductless mini-splits or combinations.

Knowledge: They should have demonstrable knowledge of energy-efficiency standards and building science (air sealing, insulation, load calculations, duct sealing, ventilation).

Customer references and positive reviews: Look for consistency, on-time accolades and comments about professionalism, transparency and good communication.

Clear written estimates: Your quote should include labor, materials and scope of work; no vague or open-ended pricing.

Training: They should be willing to show their certifications or talk about their training.

Transparent communication and customer care: You should feel like they’re listening to you and explaining their work in clear terms.

Glossary

ACCA: Air Conditioning Contractors of America; publishes national HVAC installation and quality standards.

Air Sealing: The process of closing leaks, cracks and gaps in a home’s building envelope to prevent unintended airflow.

BTU: British Thermal Unit; a measure of heating or cooling output.

Combustion Safety Test: Inspection of gas-fired appliances to ensure proper ventilation and safe exhaust.

Duct Sealing: Repairing and sealing HVAC ductwork to prevent air leaks and improve airflow efficiency.

ENERGY STAR®: A U.S. government-backed symbol for energy efficiency, managed by the EPA and DOE.

Heat Pump: A heating/cooling system that moves heat in or out, rather than generating it via combustion.

HVAC: Heating, Ventilation and Air Conditioning

Load Calculation (Manual J): A standardized method (published by ACCA) to determine the correct size HVAC system for a home.

Mastic: A durable sealant used to seal ducts; more effective and long-lasting than standard “duct tape.”

QCN: Quality Contractor Network (e.g., regional networks like TVA EnergyRight’s that pre-vet contractors for quality/insurance/experience).

R-value: A measure of an insulation material’s resistance to heat flow; the higher the R-value, the better its thermal resistance.

SEER2: Seasonal Energy Efficiency Ratio; a metric for air conditioner / heat pump cooling efficiency (new standard).

Supply / Return Ducts: The ducts that deliver conditioned air to living spaces (supply) and return air back to the HVAC system (return).