From waste to watts: How General Mills turns yogurt into power.

It might sound like science fiction, but in Murfreesboro, Tennessee, yogurt waste is helping power the grid. At General Mills’ massive facility—home to iconic brands like Pillsbury and Yoplait—a clever use of dairy byproducts is reducing emissions, improving resilience and offering a model that other manufacturers could follow.

Here’s how it works — and why it matters.

What’s in yogurt waste? And why it’s powerful.

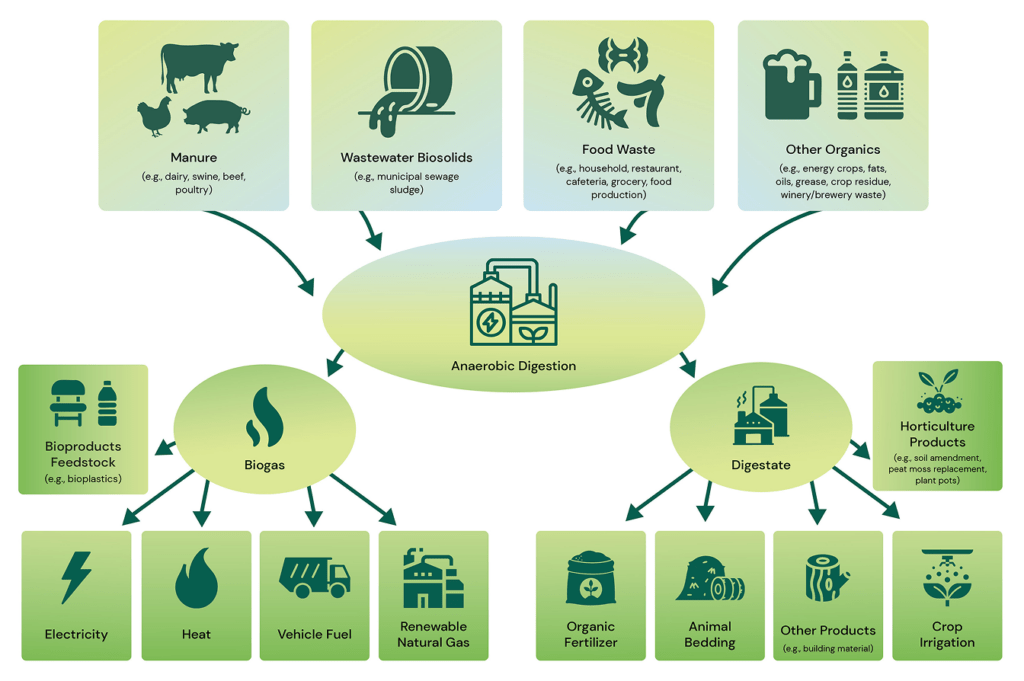

Greek yogurt production generates a significant amount of byproduct known as acid whey — a nutrient-rich liquid that’s expensive to dispose of and challenging to manage. But it also happens to be full of organic material that breaks down well in a process called anaerobic digestion.

Anaerobic digesters are machines that break down food and plant waste using tiny microbes (like bacteria) that don’t need oxygen. As the microbes consume the waste, they produce a methane-rich gas, also known as biogas, which can be used to generate electricity.

At General Mills’ Murfreesboro plant, that biogas is used to power a 1.6-megawatt generator, supplying energy right back to the facility and offsetting fossil fuel use. Even better? The leftover material (digestate) can sometimes be repurposed as fertilizer.

Sources: epa.gov; generalmills.com

Why is the Middle Tennessee plant location unique?

The General Mills site is unique not just for its size — it’s one of the largest Yoplait producers in the country — but for its on-site wastewater treatment plant. Plus, with a demand load exceeding 15 megawatts — one of only four General Mills plants globally to reach that threshold — the facility’s energy performance has a significant impact on both operational efficiency and sustainability goals. When the facility expanded to accommodate Greek yogurt production, it invested in an anaerobic digester to handle the acid whey and other organic waste.

With support from federal clean energy tax credits and strong technical assistance from Middle Tennessee Electric (MTE), the plant was able to safely integrate the generator into the grid. That partnership was essential to making the system viable — not just technically, but economically.

Daren Kaiser, Global Energy Strategy Leader for General Mills, says, “We got 40% of that cost covered by a federal rebate, but the real win was Middle Tennessee Electric’s willingness to partner with us. MTE was with us every step of the way. They probably worked harder than our contractors to make sure it came together. That kind of partnership makes innovation possible.”

What’s the impact?

The anaerobic digester is a low-emission, high-reward system that helps General Mills:

- Reduce a facility’s Scope 1 emissions (by burning natural gas).

- Save on waste disposal costs.

- Generate renewable electricity.

- Increase energy resilience for a plant that operates 24/7 and can’t afford outages.

- Keep valuable nutrients out of landfills or waterways.

The anaerobic digester at General Mills provides a powerful win-win for business and the environment. Beyond reducing Scope 1 emissions and cutting waste disposal costs, it generates clean, reliable power — perfect for a plant that can’t tolerate downtime. Plus, the digestate, a semi-solid material left over from the anaerobic digestion process, can be used as fertilizer, keeping nutrients in the loop rather than allowing them to leach into landfills or waterways.

Source: cen.acs.org

Can other industries do this, too?

Yes! Anaerobic digestion is also being used by:

- Food and beverage manufacturers (especially dairy, meat and produce)

- Breweries (spent grains and yeast waste)

- Agriculture (manure and crop waste)

- Municipalities (food scraps, sewage sludge, biosolids)

The keys to success? A consistent waste stream with sufficient volume to justify the system, and strong local utility partnerships to help manage grid integration and incentives.

For companies under pressure to meet sustainability goals without sacrificing uptime or margins, anaerobic digestion offers a compelling win-win. What starts as a byproduct of creamy Yoplait ends up fueling the plant that makes it. In a time of increasing energy demands, turning waste into energy might be one of the smartest, most scalable strategies available.

Sources: epa.gov

Ready to take the next step?

Connect with your local power company or with one of our TVA Energy Experts to explore energy-efficiency options tailored for your business or facility.